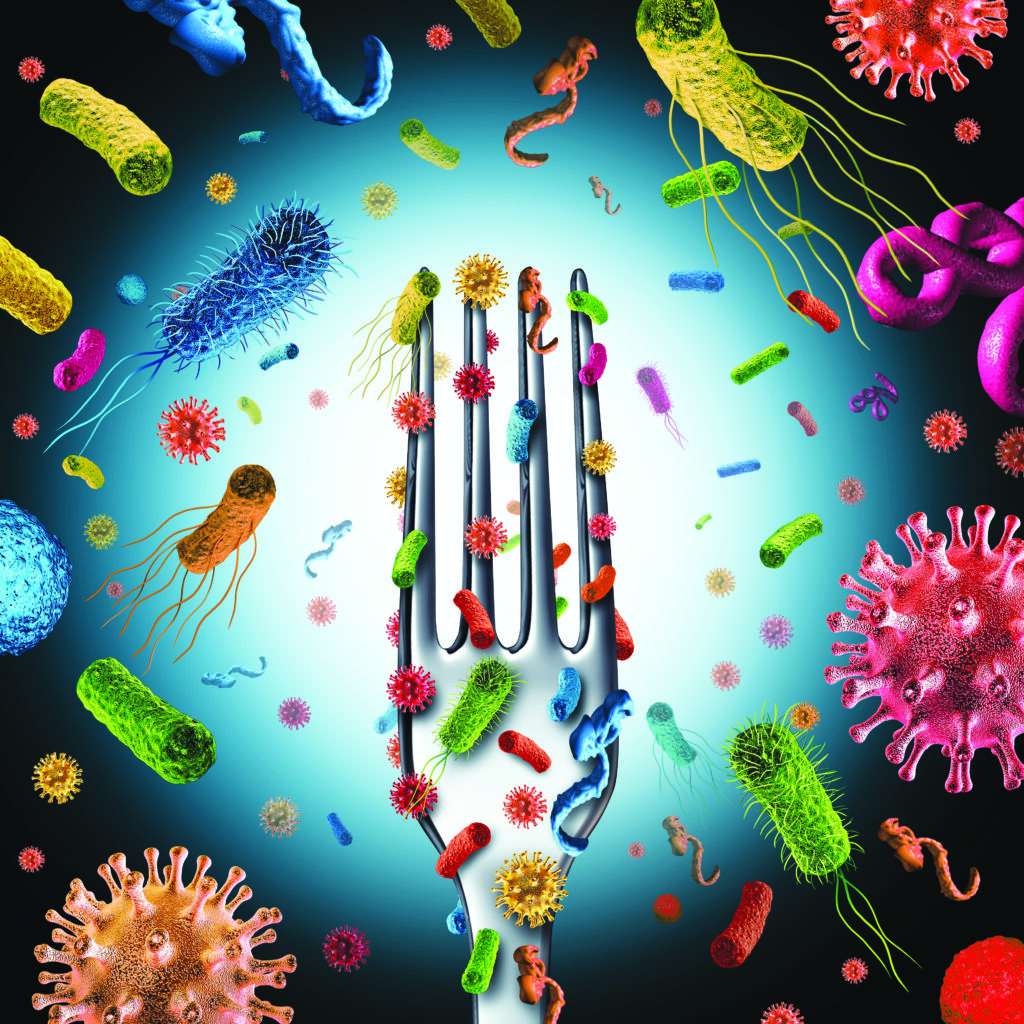

Biological hazards in the processing and preparation of food refer to the presence of harmful microorganisms, such as bacteria, viruses, parasites, and fungi. They threaten human health if ingested. These hazards can contaminate food at various stages, from production and processing to preparation and serving. Experts discuss the challenges and solutions with Keerthana Sundar.

Here’s an overview of the primary biological hazards plaguing the food industry:

• Bacteria: pathogenic (disease-causing) bacteria like Salmonella, Escherichia coli, Listeria, Campylobacter, etc. cause foodborne illnesses and are most often associated with undercooked or contaminated food.

• Viruses: Norovirus and Hepatitis A virus can be transmitted through contaminated food or water. The former causes gastroenteritis whereas the latter affects the liver.

• Parasites: Protozoa and helminths like Giardia, Cryptosporidium, and Trichinella can contaminate raw or undercooked foods, particularly in meat and seafood.

• Fungi: Mycotoxins are toxic substances produced by molds that can contaminate crops such as grains, nuts, and fruits. Aflatoxin, produced by Aspergillus fungi, is an example of a mycotoxin.

• Toxins: Bacterial and shellfish toxins can lead to food poisoning endangering the health of consumers.

• Allergens: Common allergens include peanuts, tree nuts, milk, eggs, soy, wheat, fish, and shellfish. Cross-contamination and inadequate allergen labeling can lead to allergic reactions.

There are various routes of contamination including through raw ingredients, cross-contamination, inadequate cooking, and contaminated water.

Clean India Journal spoke to credible experts to seek their valuable opinions on how to tackle the aforementioned challenges.

Abhinav Khobragade, Entrepreneur at Cafe Pizza Rocks outlined proactive steps the food industry should take to prevent microbial contamination during food processing:

• Hazard Analysis and Critical Control Points (HACCP): Follow a good systematic approach to identify, assess, and control potential microbial hazards at critical stages of food processing

• Strict Hygiene Practices: Enforce personal hygiene measures among food handlers, including regular handwashing, use of protective clothing, and mandatory health checks

• Employee Training: Provide comprehensive training programs to educate personnel about microbial contamination risks and proper food safety practices

• Temperature Control: Employ precise temperature controls during cooking, cooling, and refrigeration to inhibit the growth of harmful microorganisms

• Proper Storage: Ensure appropriate storage conditions for raw materials and finished products to prevent microbial proliferation

• Regular Monitoring: Conduct routine inspections and microbial tests of equipment, surfaces, and raw materials to detect and address contamination risks

• Sanitation Programs: Implement cleaning and sanitation protocols for equipment and processing areas to eliminate potential microbial sources

• Quality Assurance: Implement stringent quality control measures to maintain high standards and reduce microbial contamination

• Supplier Verification: Verify the safety and quality of raw materials through assessments of suppliers and their production practices

• Traceability Systems: Establish traceability systems to quickly identify and remove contaminated products from the market, minimizing the impact of potential outbreaks

Active participation in industry initiatives can help enhance overall food safety practices.

Abhinav Khobragade

Cross-contamination of pathogens between raw and cooked food in commercial kitchens can be minimized by separating work areas, color-coding systems, usage of gloves, and collaboration with health authorities to stay informed about the latest regulations and guidelines related to food safety. Active participation in industry initiatives can help enhance overall food safety practices.

Current technological advancements to improve foodborne virus detection and control include diagnostic tools using techniques like Polymerase Chain Reaction (PCR) and Clustered Regularly Interspaced Short Palindromic Repeats (CRISPR)- based assays. Nanotechnology provides an impetus for enhancing sensitivity while blockchain and IoT enable better traceability in the food supply chain. Advances in hyperspectral imaging and spectroscopy aid in detecting contamination. Additionally, machine learning algorithms are employed for data analysis and prediction. All the aforementioned technologies ensure safer food products for consumers.

Challenges

Challenges an organization faces while handling seafood include the risk of cross-contamination. Shellfish and seafood allergies are common and the prevention of cross-contact with other ingredients is crucial. Sourcing sustainable seafood is difficult with customers routinely seeking eco-friendly options. Availability and quality can vary seasonally, impacting menu planning and customer expectations.

Ashutosh Jaiswal, a Food Safety Professional opined that in the complex world of food processing and preparation, the safety of consumables is paramount. Biological hazards can compromise both the quality of the food and, more critically, the health of consumers. Primary sources include raw materials, equipment, and even personnel involved in the food production chain. These hazards lead to foodborne illnesses, outbreaks, and product recalls, posing serious threats to public health and the reputation of food-related businesses.

The common challenges include microbial contamination, cross-contamination, inadequate hygiene practices, and temperature control. Maintenance of proper temperature control throughout the food processing chain is crucial as inadequate refrigeration or cooking temperatures can allow pathogens to survive, posing a persistent threat to food safety.

Common solutions to mitigate challenges include the incorporation of stringent quality measures, adoption of HACCP principles, employee training and education, strict sanitation protocols, and adapting newer innovations in technology and supply chain management.

Maintenance of proper temperature control throughout the food processing chain is crucial as inadequate refrigeration or cooking temperatures can allow pathogens to survive, posing a persistent threat to food safety.

Ashutosh Jaiswal

CIJConnect Bot-enabled WhatsApp

CIJConnect Bot-enabled WhatsApp

1 comment

I do believe all the ideas you’ve presented for your post. They are really convincing and will certainly work. Nonetheless, the posts are too short for novices. May just you please lengthen them a little from subsequent time? Thanks for the post.