Indian Delegation’s journey to the headquarters in Minneapolis, USA

Minneapolis set the stage for an inspiring visit for the Indian delegation hosted by Tennant Company, the world’s leading cleaning equipment manufacturer. The Tennant headquarters stands as a beacon where innovation meets sustainability, where products endure for decades, and where many employees stay for 25 plus years! Mohana M, Editor, brings you a first-hand account of this immersive four-day experience alongside Tony Chazhoor, MD, IP Cleaning India Pvt. Ltd (a Tennant Group of Company); Manoj Parekh, MD, OCS India; Saurabh Agarwal, MD, Unify Integrated Facility Management; Bikram Chadha, MD, Impression Services Pvt. Ltd; Parvez Sheikh, Procurement, All Services Global Pvt. Ltd and Anil Sathe, GM-Sales, IP Cleaning India Pvt. Ltd.

Also known as the City of Lakes, with over 19 water bodies within the city, Minneapolis is home to more than 16 Fortune 500 companies and several MNCs. Tennant Company, established in 1870 in Minneapolis, Minnesota, began as a small woodworking business founded by George H. Tennant and today is a major global player in the cleaning industry with operations across North America, Europe, the Asia-Pacific region, and other parts of the world.

The four-day tour was full of experiences, learnings, understandings, sight-seeing, and bonding among the Indian delegation, and for many of us, it was the first trip to Minneapolis.

Tennant Company’s world headquarters is a new facility that reflects its commitment to innovation, sustainability, & employee well-being and supports research and development (R&D) efforts. With over 150 years of history, the Tennant facility showcases the journey of cleaning equipment from the initial motorised floor cleaner made in 1932 to the latest autonomous floor scrubber powered by BrainOS® Robotics Platform, along with several other autonomous machines that are under trial.

The fascinating three-story Global Corporate Campus features a more flexible workspace, with open areas designed for collaborative teamwork. Uniquely redesigned in 2020, each floor welcomes visitors with motivational messages displayed on its colour-coded walls. The long corridors of the manufacturing facility, adorned with stringent safety protocols, illustrate the evolution of technologies from yesterday to today and into the future.

The intersection where the robots take their trial rounds, showcases the precision involved in modelling AI to meet customer needs. While the components of each of the machines may be common, the customisation is geography-specific and that brings about the much-required customer satisfaction. Constantly innovating and remodelling its equipment, this unit has gradually increased its larger machines’ production capacity. Several of the latest models of large sweepers provided an interesting experience for the Indian delegates, with some of them getting behind the wheel for a memorable ride.

The well-planned visit enabled discussions on the workshop floor enumerating the varied manufacturing processes right from receiving the raw materials to the exit of the finished product, the research and simulation labs, and the conversations with ‘those who interact every moment with each part of the machine during its making’ at the Tennant factory. Their passion was evident as they led us through each of the passages, explaining the progress of machines under production. And their attachment to some of the creations was heart-warming.

Living true to its culture of being a people-centric company, the 25-year Club members and 50-year Club members had a dedicated wall carrying their pictures of workers who have remained with Tennant for so many years. It may be one of the few companies in the world that has more than 400 out of the 4,000 plus employees who have served more than 25 years! The Tennant 25 and 50 Club members wear badges and jackets with the 25 and 50 logos. There is something about the culture of the Tennant Company, which one can feel but cannot explain.

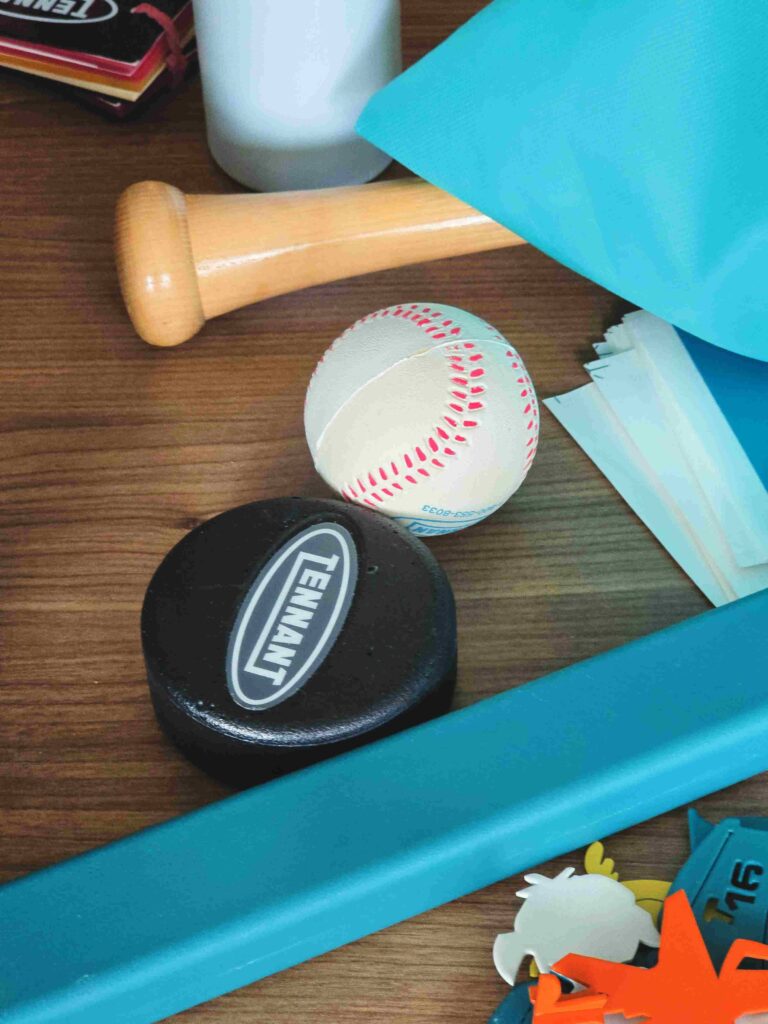

Speaking of those who have retired and are still attached to the company through the Retiree Club, they still get together. The second floor of the corporate building showcases souvenirs brought back by the retirees. Bats, balls, miniature scrubbers, badges, caps, Halloween masks…more than forty decades old still sit there as reminders of the past glory.

Technology & People-centric Approach

In a candid talk during our interaction, David W. Huml, President & Chief Executive Officer of Tennant Company, passionately addressed the current issues of technology adoption, sustainability, and a customer-centric approach to success in the cleaning industry. Here are the excerpts of the Q&A:

Technology driven solutions for cleaning – how is it enabling quality results vis-à-vis the cost and time factors? Where is the change happening today?

Every vertical market in every geography around the world is experiencing a change, and mechanisation or automation is providing greater productivity in cleaning applications.

In some cases, we see a shift from manual mop and bucket cleaning to mechanized solutions. This is driven by the need for increased productivity, higher cleaning standards, and addressing labour shortages or high labour costs. In other geographies, we see a growing demand for robotic solutions due to similar factors: labour availability, cost, and the need for consistent cleaning standards. These factors are driving the adoption of both mechanized and robotic equipment to boost productivity. We are beginning to design more products, and more importantly, focus our value proposition toward the more altruistic goal of robotics and automation and think about Equipment as a Service (EaaS) or Robots as a Services (RaaS). The cost of paying for the complete robotic machine lowered to a monthly payment where you don’t have to borrow money to pay for the robot. We have done this well in other countries like Brazil, which has dynamics similar to parts of India.

What according to you would be the much-wanted solution globally in the near future?

Customers in Europe primarily adopt mechanised cleaning to overcome labour scarcity and cost. In other geographies and applications, we also see the need for more consistent cleaning and greater productivity. With robotic equipment, it is not just the robotics but the continuous improvement of the robot’s performance over time, not only on the ground and its application, but also in the design, power consumption and power source.

Having insights into the data coming out of the machine to understand the actual usage, health, and location provides other points of value to the customer. It is about automating the cleaning option and improving the overall business of cleaning. Customers today are very involved in the equipment, and its specifications, training, and maintenance costs. We see a future where we take that burden off our customer’s minds and hands as they can pay for the cleaning, and we can reliably deliver it to them.

How does AI help in predictive maintenance?

There are many applications for AI across our business and value proposition to our customers. We have done a pilot taking our many decades of service records and using them through machine learning models to become better at reactive maintenance. As a call comes in, whether it is a human call saying, “Hey, my machine isn’t working,” or the machine telling us directly that something is wrong, the same is linked up with the machine learning model.

With all those years of servicing machines, we can more accurately predict what is wrong with the machine, and we now have multiple ways of cracking that in the field with the customer, telling the machine remotely how to correct itself or asking for the customer’s aid in doing some preliminary troubleshooting. The result is that when we send the service technicians for repair, they are going to be better equipped with troubleshooting data, have the necessary tools and parts to perform the repair the first time, and get the customer up and running and, in some cases without the customer even knowing they had a problem. That is a fantastic outcome for the customer. That’s the ultimate goal – to move from reactive maintenance to predictive maintenance.

One of your hallmarks is a customer centric approach. How do you see it differing in various geographies, including India, where much customization is required?

We have a number of assets or capabilities as a company. We have products, technology, go-to-market models, a white-glove customer experience that we can deliver over the phone or via an app, and several assets we can bring to help solve problems. But as a manufacturer, we must resist the urge to just sell what we make or works in one geography and assume it will solve the problem in a local geography like India. When I think about an approach to India, it is to talk to customers, listen to their problems, go on-site and see how they are cleaning today, see what challenges they have and the problems they are trying to solve. When you have defined the problem statement, come back and look at our assets and capabilities and say, “Will any of these efficiently solve the problem for the customer?” One of the traps that manufacturers fall into – say you have a company founded in Germany and you serve German customers really well – is to literally shift that product, service and technology, to another geography like France, India, the US or Brazil and say “Why won’t this work here? This works in Germany!”

This process of listening to and engaging with customers can lead to collaborative solutions, as it is always an iterative journey. You develop it on a small scale with iteration; when it works, you can scale it and offer it with a high degree of confidence to everyone. But it is a process. It’s not a one-size-fits-all solution.

What initiatives are you implementing to promote sustainability in your product offerings?

Sustainability in all its facets is an increasingly popular driver for equipment decisions and its use. Sustainability at Tennant means being a good steward of the resources around the globe. It is not just from the power consumption perspective or in ways that advance our business but providing customers with tools to achieve their sustainability targets. Because our machines use water for scrubbing, it’s about water usage consumption, where the dirty water goes, and having technologies that minimise the reliance on clean water to preserve that precious asset.

We also think about the circular economy. We design our products such that they can have one, two or three useful lives which keep them out of the landfill. Increasingly, we are designing products that, when they reach end-of-life, can be disassembled and recycled into another raw material and have a useful life beyond that. We think about sustainability not just in terms of net-zero targets but holistically, as being the steward of the world’s resources and enabling our customers to being stewards as well.

We are already into extended producer’s responsibility for electronic goods in Germany. We are on the path to building our capability to recondition our own machines – where we sell a piece of equipment and provide the service, we make sure it is well-maintained. When it is ready to have a second life, we will pull the machine from the pool, recondition it to certain specifications and put it back into service so the customer can get good productivity out of it.

Customer Centric Approach

With the best practices put in place, producing a sustainable product, and meeting the net-zero goals has been a progressive approach with Tennant. Rusty Zay, Global COO of Tennant Company, spoke at length on the product offerings and meeting sustainability & Net Zero goals. Excerpts:

What initiatives are you implementing to promote sustainability in your product offering and how do they impact your competitive advantage?

We have our own net zero-goals to be achieved by 2040. We have made significant sustainability strides with our EC-H2OTM technology, which converts water into an innovative, detergent-free, solution that cleans effectively, saves money, and reduces environmental impact compared to daily floor cleaning chemicals. That’s an example of a sustainability opportunity for people to use in their facility.

Another opportunity we have been working on is electrification in battery technology. The standard lead acid of the technology curve into lithium-ion electrification is getting sustainable as lithium-ion batteries last longer with an opportunity charge, so you can use it more frequently without depleting the performance of the battery, and the customer not having to throw away batteries on a regular basis.

The third area is electrifying all our machines. We have a wide range of high-quality, high-performance products, and we are currently innovating our designs. Our goal is to create solutions that meet customer needs for performance and runtime in a battery that can operate fully without an engine.

What differentiates your products from competitors in the market, and how do you ensure your sales teams effectively communicate this value to potential customers?

For markets like India, it is the local sales and service teams and our ability to provide good customer experience on the ground. In our industry, that is truly where we have the competitor edge. When you have an excellent go-to-market footprint – in sales, customer service and geography – the person who provides the best customer experience is the market leader, regardless of the products in your portfolio. We are on a relentless path when we choose to have a go-to-market footprint in any geography such as India. We continuously pursue the creation of a sales, service, customer service and back-office ecosystem to make sure the customer buys the right product, uses it appropriately to get the job done and is happy and confident that if ever there is an issue, it will be taken care of. That is the winning formula we are pursuing in all the geographies in which we operate.

How do you gather and leverage customer feedback to enhance your product offerings and customer experience?

A customer satisfaction metric is used, and in our key direct markets, we survey our customers on a one-on-one basis from a product experience perspective, right from after we deliver a product up to parts and consumables. If we have direct service, then the survey tagged to the customer is from the service experience perspective. Once we survey the customer, we get that data back and act on any negative feedback. We call the customer directly and correct the negative experience, finally closing the loop. But the key is that we use all that data to inform thematically how we need to improve our processes. We have been using this for four years, and we are broad-based enough to get customer feedback on scale.

The other feedback is on products. We do “Voice of Customer” work and qualitative and quantitative research. We also do ethnographic research where we go into the customer’s environment: we don’t ask questions but observe them cleaning and using their equipment to look for unmet or unspoken needs. We observe their compensatory behaviour, which is that they will not tell you even if you ask them, but they will just do it. That’s where you can observe the real problem and how people are trying to manage the cleaning process on their own. This is not a survey at all but based on observation. We go in with a small group of people and watch them clean the facility. You might observe that they clean the equipment but don’t use some functionalities at all.

We do broad-scale development with our new products and get feedback from customers on the prototypes. We have them test pilot projects, which allows us to get feedback. These are early-stage prototypes, not finished products, and we gather feedback throughout the development process from as many customers as feasible from different geographies.

Getting on to the bonding part, the delegation experienced a cruise on the Mississippi River, the visit to the Mall of America and a tour of the twin cities of Minneapolis and St Paul.

The closing effect of the entire tour got a nostalgic flavour when a street singer got on to his guitar singing the old classics of English music, which spontaneously set the rhythm to our feet.