There is often a gap between Standard Operating Procedures and Key Performance Areas. The success of a management depends on how it walks the thin line. Often there can be disruptions between what is stated on paper and on-ground reality. Clean India Journal’s Manka Behl speaks to experts in the industry on how to bridge the gap consistently

India’s facility management (FM) industry is growing at a double-–70 billion today, the sector is projected to cross $80 billion by 2025, according to industry estimates.

On paper, the industry appears mature. Contracts are detailed, audits are frequent, and Standard Operating Procedures (SOPs), Service Level Agreements (SLAs) and Key Performance Indicators (KPIs) dominate service agreements. Performance is measured, tracked and penalized with increasing precision.

Yet, on the ground, service delivery continues to struggle with inconsistency. Despite the widespread adoption of SOPs and KPIs—tools meant to standardise operations and improve service quality—implementation gaps continue to define daily realities across facilities.

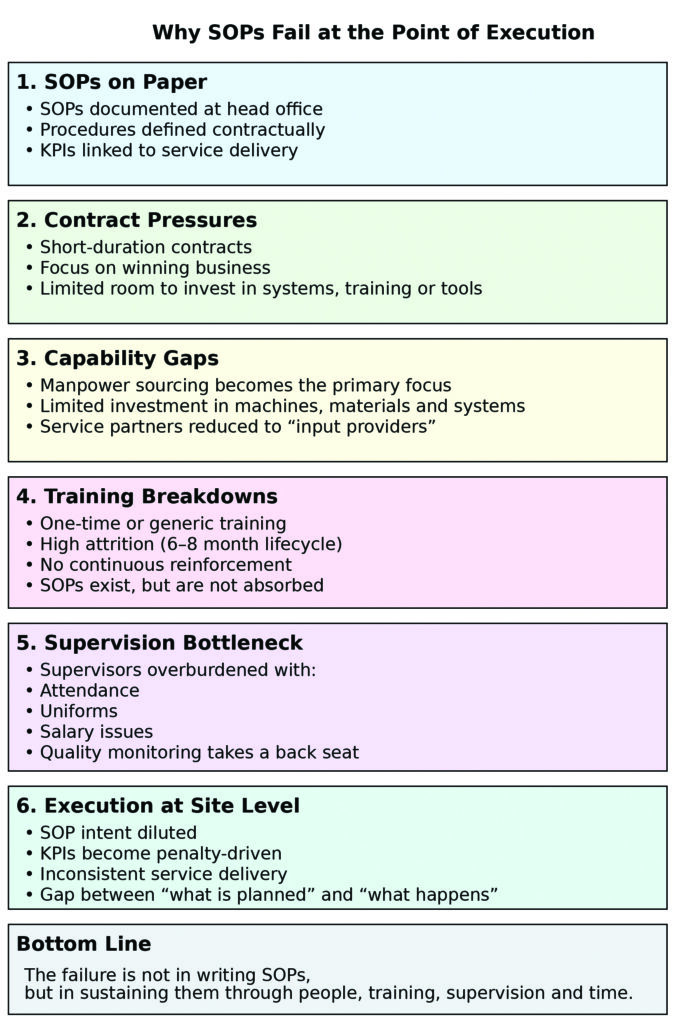

As the Indian FM market scales up, industry veterans are asking an uncomfortable but necessary question: Why do systems designed to ensure uniform service delivery so often fail at the point of execution?

This contradiction—between documented processes and lived practice—formed the core of a candid discussion at the recent Clean India Show, where experts examined why SOPs and KPIs struggle to translate from files and dashboards to the field level, and what the sector must rethink to bridge this widening gap.

SOPs Ok, KPIs No

During the discussion, panellists acknowledged what many FM professionals experience daily: SOPs and KPIs are no longer optional. They are embedded into contracts, audits and procurement frameworks. However, instead of becoming enablers, they have increasingly turned into pressure points—especially for service partners.

Saji C Sebastian, Founder and Adviser of FM Future Labs, said, “ While SOPs have become the norm, KPIs have become a pain, especially when as a service partner or a service provider we enter into any agreement or a contract, KPI has become the challenging part.”

He added that many service partners hesitate to even consider certain contracts because of how KPIs are structured.

The discussion also highlighted how the role of SOPs and KPIs changed significantly over the years. While the earlier frameworks were simpler and more balanced, they seem to have now become far more measurement-driven, experts felt.

According to Edward Dsouza, CEO of SMC Integrated Facility Management Solutions Limited, contractual language and industry jargon have emerged over time. “A lot of people get confused with something called scope of work, KPI, SLA. These jargons started to come in the early 2000s when the industry tried to flourish and everybody wanted to put some kind of a check to the contractor. Eventually from the client side, it more became how do I catch or how do I penalise my vendor, not even a service partner,” he said.

Drawing attention to SOP design, the expert criticised the one-size-fits-all approach. “Most of the FM companies try to develop a standard SOP for a standard work. But every single facility is different from another facility. What you do in a pharma is not applicable in a mall, and what you do in a mall is not applicable in the office, and what you do in the office is not applicable in the healthcare sector,” said Dsouza.

Without understanding sector-specific pain points, SOPs cannot be effective, he added.

Turning to KPIs, the expert questioned the industry’s obsession with manpower numbers and stressed that they should reflect value creation rather than headcount. “KPI is something that I would describe as what is the value that you bring to the table. It’s not how many people you delivered inside the security gate. The entire focus is always on manpower,” said Dsouza.

Vinay R Deshmukh, Executive Director and CEO of FFServices, stressed the need for clarity between service providers and clients, saying that clearly defined agreements are critical to effective service delivery. “When two parties come together, there has to be an agreement defining what is expected for both the parties,” he said.

Tested By People

Beyond frameworks and contracts, SOPs are ultimately tested in the daily rhythm of operations. It is at active sites—hospitals, hotels, industrial units and public facilities—that written procedures encounter manpower shortages, supervisory gaps and the realities of execution. Here, SOPs are no longer documents to be reviewed, but practices that must be repeated, monitored and enforced, shift after shift.

For facility management companies working on the ground, the challenge is not the absence of SOPs but ensuring that they survive beyond paper and presentations.

It is from this operational lens that Shridhar Lande, Director of Nagpur-based facility management company Suvidha Services, tries to keep SOPs relevant in real-world operations.

For him, effective implementation is inseparable from leadership presence and continuous monitoring. He strongly believes that manpower stability, compliance discipline and leadership involvement determine whether procedures remain alive or become symbolic.

Speaking from nearly three decades of experience and as the leader of a workforce of over 800 personnel, Lande said the biggest challenge facing the industry today is not a lack of SOPs, but the ability to manage people consistently. “SOP implementation collapses when manpower is viewed merely as labour and not as a long-term responsibility. If you don’t take care of the workers’ security, their future and their compliance, they will never give you ownership,” he said.

Lande links this sense of security directly to SOP adherence. “When people know the company is thinking about them, discipline comes automatically. In our company, we place strong emphasis on statutory compliance, including insurance and social security benefits. We follow 100% manpower compliance. Employees are linked to government schemes and supported through insurance and death claim benefits so that their families are not left vulnerable,” he said.

Beyond manpower, he also pointed to the growing technical complexity of cleaning operations. Highlighting the increasing use of environment-friendly chemicals, mechanised equipment and changing formulations, Lande urges FM companies to ensure that their SOPs continuously evolve alongside the changes.

Further addressing the gap between SOPs on paper and actual execution, Lande placed responsibility squarely on leadership. “No matter how much training you give, unless leadership goes to the site, the gap will remain,” he said, adding that conducting surprise rounds, visiting factories and physically verifying whether procedures are being followed is crucial. “You cannot sit in the office and assume SOPs are working. Sometimes even one or two visits a month can make a big difference,” he said.

On KPIs, Lande described them as tools to enforce discipline rather than fear. He acknowledged that penalties are sometimes necessary but said his organisation attempts to redirect them constructively. “If we have to impose a penalty, the money goes into a charitable trust. Our staff know that if they make a mistake, the money is not going into someone’s pocket, but towards something meaningful,” he said.

For him, the message is clear: SOPs and KPIs succeed not through enforcement alone, but through leadership presence, manpower dignity and operational realism.

Starting Small

Yet, even as manpower remains the backbone of service delivery, the harder question is not hiring but holding on. And it is this cycle of attrition, retraining and loss of continuity that repeatedly weakens even the most well-documented SOPs, as industry voices pointed out.

According to Dsouza, the real challenge in SOP implementation lies not in documentation, but in sustaining practices amid constant workforce churns. “Once you draft a standard operating procedure, and if you do it sector-wise, the execution team cannot be general. A guy who operates a mall will not know how to operate a pharma,” he said.

The best solution, as per Dsouza, is to focus on building subject matter expertise within organisations. “Start somewhere small. Even one or two guys per sector — train them well and make them subject matter champions,” the expert advised.

Talking about more reasons on why SOPs often fail on site, Sebastian said, “How I see SOPs is it is a document of 20 to 50 odd pages. Organisations have 50 SOPs with version one, version two, version three, signed off by multiple people. These documents rarely translate into practice. The people who are actually driving the SOP have never read those 50 pages.”

According to him, the only way to bridge this gap is through effective training. “In today’s digital world, SOPs also need to be simplified and digitised. Make a small video clip, a flowchart. Translating SOPs on ground can easily be achieved by digitising them,” he suggested.

Deshmukh proposed a ‘buddy system’ to deepen implementation. “If somebody new comes in, there has to be somebody who will shadow that person, observe, guide and correct,” he said, adding that such interaction helps SOPs reach the grassroots level and become “a way of life”.

Where Systems Meet Responsibility

As facilities become larger and surfaces more complex, the science behind cleaning machines, chemicals and trained application has emerged as a defining factor in service delivery.

Shashikant Manapure, Director of Nagpur-based Spick and Span Professional Services Pvt Ltd, entered the cleaning and hygiene space in the mid-1990s. According to him, the core misunderstanding even today lies in underestimating the technical knowledge required for cleaning different surfaces. “Every surface is different. Marble, glass, carpet, washrooms—each needs a different chemical, a different dilution and a different tool,” he said, adding that incorrect use often leads to permanent surface damage.

Manapure pointed out that infrastructure has changed drastically over the decades, but cleaning practices have not kept pace. “Earlier buildings were simple. Today we have Italian marble, glass façades, specialised flooring. You cannot maintain today’s infrastructure with yesterday’s methods,” he said, adding that cleaning “should not be treated as unskilled work”.

Talking about SOP creation, Manapure said that procedures are designed both internally and in alignment with their client requirements, especially in sensitive environments. “In hospitals and labs, we follow their SOPs as well. We stay updated with audits, new chemicals and revised protocols, and then train our manpower accordingly,” he said.

Highlighting manpower challenges, Manapure agreed that people management remains the most critical issue in facility management. “You can buy machines and chemicals, but if manpower is not secure, trained and motivated, nothing works,”

he said.

Manapure also spoke about the growing role of technology, including robotic cleaning and concentrated chemicals, while cautioning against blind adoption. “Facility management today is a blend of science, skill and awareness. This industry is not just about cleaning. It is about understanding materials, chemistry, equipment and human behaviour,” he said.

Cost Of Saying ‘Yes’

Industry experts feel that many service providers continue to operate from a position of fear, agreeing to every client demand even when execution is not viable.

Sharing his experience as a consultant, Sebastian said that when he started out, he initially took on most assignments that came his way. “In the first 12 months, I was groping in the dark; I would say yes to most assignments. Over time, I realised that many organisations struggled not because of lack of intent, but because they did not know how to understand a client’s problem or convert it into a workable solution,” he added.

Bringing the focus to the fragmented nature of the facility management market, Deshmukh stated that though the size of the Indian market is at around Rs 1.2 lakh crore, no single player commands even a 10% share. “This market is so fragmented that there is no clear definition of small, micro or large,” he said.

Sebastian advised service providers to recognise their own value. “We are in this workspace because we are subject matter experts,” he said, adding that expertise and know-how were the “real differentiators, not headcount”.

Challenging the label of “unskilled labour”, Deshmukh pointed out that facility services increasingly involved operating expensive machinery and maintaining high-value infrastructure. “When you buy a machine worth 10 or 12 lakh rupees, would you give it to someone unskilled,” he questioned.

According to him, recognising this value internally was critical. “When we translate this understanding to our own teams, we build confidence not just in ourselves, but in our people,” said Deshmukh, stressing that service providers needed to engage with clients as partners, not as subordinates.

Adding another layer to the dialogue, Sebastian said that confidence must also be rooted in business readiness. “Service providers often failed to assess whether a contract timeline justified investment in training and systems. Any contract of 12 months or less is actually a loss,” he said, adding that having a basic understanding of what the business service providers are entering into is also important.

Another important factor according to him was capability. “When I look at it today, we act as two input providers – people and resources. 100% manpower comes from the service partner; in most contracts, materials and machines are not supplied by service providers. In my experience, only 20% of the accounts or contracts have material, and maybe 15% of the contracts have material and machine,” said Sebastian.

The expert added that beyond sourcing manpower, service partners also need the ability to mobilise, train, retain and continuously backfill resources. “If service providers truly want to operate as service partners and introduce SOP and KPI-driven delivery, the business has to be viewed differently; it needs to be holistic,” he said.

Cracking The Code

As the discussion moved towards execution at scale, speakers turned their attention to training, technology and the supervisory layer—often cited as the “weakest links” in service delivery.

Dsouza reflected on how facility companies earlier invested heavily in physical training centres. “There was a time when every FM company took pride in setting up a training centre,” he said, recalling how dedicated facilities once played a central role in skill-building.

However, he pointed out that as operations expanded geographically and manpower churn increased, this model became impractical. “Earlier, the businesses were smaller, in early 2000s. Now it has become large-scale, and it is not practical to get people to travel using public transport to get trained, and an important question – will you retain them?” he asked, adding that in his experience, the life cycle of a housekeeping associate rarely extended beyond six to eight months.

“They continue to find a better job as a supervisor, in-charge or a peon. The industry is growing and we will keep needing people,” he said.

According to him, the answer to this problem lies not in larger infrastructure, but in simplifying training delivery. “Instead of going to a training centre, I bring the training to your door,” he said, explaining how short video-based modules had replaced lengthy manuals and exhaustive SOP documents.

“You don’t have to make a large number of videos. If you just look at cleaning, there are four or five steps,” said, Dsouza, adding that a small set of clear visual instructions are often more effective than dozens of written procedures. “Don’t do twenty or thirty SOPs,” he said, noting that neither clients nor operations teams referred to them consistently.

He further suggested that even without formal learning platforms, basic tools could make a difference. “You don’t need to make a heavy investment. Just make a group and send the videos on WhatsApp. These videos can even be soundless,” he said, explaining that daily repetition during briefings could help standardise practices over time.

Drawing his experience in managing large facilities like airports, Sebastian highlighted the challenges he faced. “All service partners had different service standards and to bring them all to a common page was a real challenge. To ensure that, the airport had to set up our own SOPs to ensure it gets implemented on ground,” he said.

Adding that they used digital checklists and QR-based tools helped monitor performance, Sebastian stressed that supervision was critical. “Your supervisory level and executive cadre and above should have a minimum understanding of what your service delivery and organisational values are. If that’s not right, no SOP can cascade down,” he said, stressing that this layer could not be filled arbitrarily.

The expert advised that training needed to be continuous, not one-time. “The only way to continuously develop your team members is training,” he said, while also urging organisations to move beyond rigid headcount-based thinking.

Questioning commonly accepted productivity norms, he said, “Everybody says five thousand, six thousand square feet per person, but nobody asks whether the person is using a ride-on machine, a walk-behind, or robotics. Meaningful planning requires understanding actual work cycles – how much time does your person take to clean a washroom? But we don’t focus on these numbers.”

Pointing out that without such internal benchmarks, service providers often asked clients the wrong questions. “Knowing our subject deeply and having a middle layer that can think and drive SOPs on site, is the first requirement,” he said, adding that technology should only supplement—not replace—this foundation.

“I think we crack the code at this stage,” he concluded.

CIJConnect Bot-enabled WhatsApp

CIJConnect Bot-enabled WhatsApp