Do I look at the pricing or do I look at utility? Do I buy a few or many in one go? This and many such doubts creep into the minds of those getting into the laundry business. Clean India Journal’s Manka Behl puts together some expert advice

As India’s organised laundry sector scales up, machines are no longer confined to the backroom—they are quietly setting the rules of the business.

The Indian commercial laundry machines market was valued at over $138 million in 2024 and is projected to reach nearly $250 million by 2033, according to Deep Market Insights, a global research and consulting firm.

But as machines absorb a growing share of capital, uncertainty over equipment choice remains one of the most common decision points for Indian laundry operators. They are either increasingly over-investing or mis-investing in equipment, often before establishing clarity on business model, processing load and long-term operating needs.

These concerns were reflected in a panel discussion on ‘How to pick the right machine for your laundry’ which was held during the 21st edition of the Clean India Show, co-located with Laundrex India. The discussion began with the most common question raised by operators – which machine is the right fit for one’s laundry business?

Clarity before Capacity

The laundry equipment buying decision—whether for a new entrant or an expanding operator—must begin with absolute clarity on the business model, segment focus, and load calculation was the advice from experts during the interactive session.

Addressing the audience, machine distributor and laundry consultant Akash Dharamsey, who is also the Director of ADD Laundry Concepts Private Limited, underlined one of the most common mistakes entrepreneurs make. “They need to be clear about their business model. We get a lot of calls from people wanting to step into this business who say we want to wash 5,000 clothes per day and the budget is unlimited. But this alone is not enough,” he said, adding that volume alone does not define the right machine investment.

According to him, the first and most critical step is to be clear about the business segment—whether the operation is commercial, institutional, industrial, or retail-focused. “You need to know what exactly you are going to wash, how much you are going to wash, what level of productivity you require, and how many kilograms you are planning to process,” he explained.

While acknowledging that new entrepreneurs may not have complete technical knowledge, the expert emphasized that at the very least, operators must clearly define the segment they intend to cater to. “You should know how many garments you want to process per day, how many kilograms that translates into, and whether you are targeting institutional customers or running a retail setup. This clarity is essential,” said Dharamsey.

Expansion Without Guesswork

The session became more interactive when a participant raised a specific operational query. Stating that his business was dedicated exclusively to dry cleaning, he sought guidance on what kind of machine investment would be ideal and the operational errors that could be avoided while scaling up.

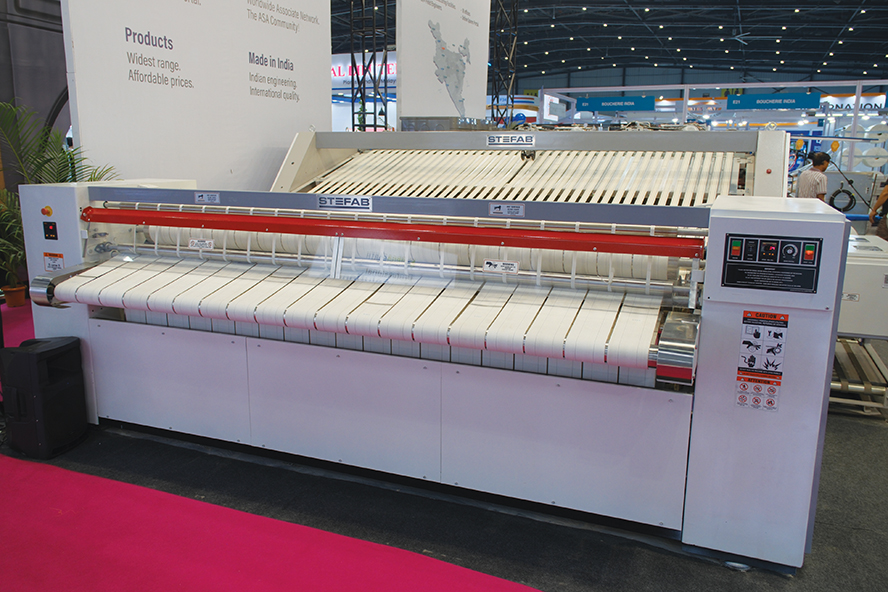

Responding to this, Zehen Arora, Director, Sales; Co-Founder at Stefab India Limited, pointed out that expansion decisions must be based on data from existing operations. “When it comes to dry cleaning, machine selection depends heavily on the type of solvent used and the type of garments being handled. If you are handling women’s wear and daily garments, then you must go with a hydrocarbon solvent machine,” he suggested.

Bringing the discussion back to fundamentals, Arora highlighted the importance of identifying what he termed the “golden number.” “In laundry today, you need to find the golden number—which is your per hour load. This calculation is critical, not just for washing but also for dry cleaning operations,” said Arora, adding that many operators overlook this aspect and end up either underutilising or overloading machines, leading to inefficiency and higher costs.

He also encouraged new operators to start small. “If you plan to buy five washers and five dryers, start with two. Keep space for expansion but start small,” the expert stated.

Price Or Cost

According to experts, one of the most common dilemmas faced by laundry entrepreneurs is navigating multiple vendors, wide price ranges and competing specifications—often without a clear framework for evaluation.

Jash Dalal, Co-Founder of The Laundry Concierge, highlighted that many launderers often get confused after interacting with multiple machine suppliers. “People meet many vendors and come back saying they want a machine priced anywhere between Rs.5 lakh and Rs.25 lakh,” he said. While some operators make quick decisions, Dalal noted that many remain unsure about what exactly they should buy and which parameters should guide their choice.

Turning to the panel experts for perspective, Dalal asked how operators should assess machines beyond brand names. Responding to this, Dharamsey advised, “Operators should already have clarity on the required capacity of the equipment. Before you decide which machine to buy, you need to take time and do your homework.”

He urged laundry owners to study consumption parameters carefully, compare machines across brands and conduct reference checks by speaking to other users of the same equipment.

The expert also cautioned operators against stopping at price comparisons alone. “Don’t just stop there; factor in maintenance costs likely to be incurred over the machine’s lifespan and then consolidate all figures to calculate the total cost of ownership (TCO) of that machine,” he said.

Once operators evaluate total cost of ownership across the life cycle of a machine, he explained, the trade-offs become clearer. “You will realise whether it makes sense to spend more upfront, have lower operating costs, thereby reducing the total cost of ownership, or whether you want to buy a cheaper machine today with higher operating expenses later,” said Dharamsey.

Importantly, he stressed on the fact that machines should not be judged in isolation. “No machine is bad. All machines are made for a particular kind of application,” said Dharamsey.

Too Much?

For many laundry entrepreneurs planning a new setup, a recurring question remains how much of the total investment should go into machinery.

Experts, however, were clear that this is not a decision that lends itself to a fixed benchmark. Responding to an audience question, the panel pointed out that capital allocation towards equipment varied widely depending on several factors, including whether the premises were owned or rented, the size of the operation, and the extent of civil and interior work involved. “As a result, assigning a standard percentage to machinery costs is neither practical nor accurate,” they stated.

The Real Cost

As investment in laundry equipment deepens, operators are increasingly weighing not just upfront cost, but how machines perform, age and pay back over time.

In practice, this raises a persistent question for operators: how should operating costs and machine life be assessed across different equipment choices? “If machinery accounts for 75–80% of total capital expenditure (capex) in a laundry setup, what percentage of operating expenditure (opex) can I expect,” asked an operator.

Responding to this, Arora reframed the discussion around processing requirements and scale. “If you talk about maintenance, that is quite negligible. However rather than measuring lifespan in years, machines should be evaluated in operating hours. International manufacturers also specify machine life in terms of operating hours,” he said.

Speaking from an engineering standpoint, Arora emphasised that buyers should look inside the machine, not just at branding or price. “Always look at the components used,” he advised.

The Hidden Cost

While equipment selection and pricing often dominate investment decisions, experts cautioned that the real operational risks in laundry businesses tend to surface much later—when machines stop working and production comes to a halt.

Speakers highlighted that machine downtime remains one of the most underestimated yet critical aspects of laundry operations. “Sooner or later, every operator has to face this reality. All of us running commercial laundries know that downtime has a direct impact on the bottom line. Production lost for a day is lost permanently,” said Dharamsey.

He stressed on the importance of building redundancy into laundry operations. “Backup machines, alternative processing arrangements and quick access to service support are essential safeguards. Breakdowns are not always caused by major failures. Even minor issues can bring operations to a standstill and thus operators need to get seriously engaged in preventive maintenance,” the expert added.

The discussion also touched upon a broader industry mindset – easy availability of spare parts. Sharing his experience, an operator said, “Structured spare-parts ecosystems—both offline and online—remain limited in the laundry sector, particularly for retail operators. I have all imported machines. I had to pay 100% advance and then wait for three months to get the parts delivered. Since most of us are using imported machines, can there be a way where the parts can be easily available?”

In response to the audience’s concern, experts broadly agreed that it is neither practical nor economical for laundry operators to stock a wide range of spare parts on their own. However, the discussion also exposed a structural gap in the sector.

Unlike many mature industries that are supported by independent spare-parts distributors and service ecosystems, the laundry industry continues to rely heavily on manufacturers for components and after-sales support.

This absence of a broader supply network not only prolongs downtime but also points to an untapped opportunity—one that could give rise to specialised spare-parts suppliers and service-led businesses within the laundry sector.

CIJConnect Bot-enabled WhatsApp

CIJConnect Bot-enabled WhatsApp