The biggest ever Clean India Show offered everything that the facility management industry could ask for. Mrigank Warrier, Associate Editor and Shaik Ismail, Special Correspondent, Clean India Journal interacted with scores of exhibitors over three days to understand the pulse of the Indian cleaning industry.

Comprehensive offerings

A defining trend was the strategy of exhibitors to provide every conceivable product. “We do not like saying no to our clients…we want to be a one-stop-shop for cleaning solutions”, said Vedant Matta, Director-Sales, Charnock Equipments.

For example, JK Engineering exhibited equipment, chemicals and consumables for steam cleaning, foam cleaning, vacuuming, scrubbing, sweeping, degreasing, descaling as well as rust control.

Innovations

Charnock introduced escalator cleaners that address both horizontal and vertical surfaces, colour-coded janitor carts, a scooty mop with a parabolic front design to efficiently gather dust, and IoT-linked machines for fleet management. Buzil Rossari showcased nano-coated urinals that neutralise bacteria, while NGM Asia Pacific demonstrated a 2-in-1 hand wash-cum-hand dryer.

Urban Hygiene’s Spacevac High Level System can clean up to 50 ft above ground level without an access ladder, and Think Hygiene’s new carpet cleaning system moves away from traditional shampooing; the process uses no water, ensures carpets are dry within twenty minutes and uses all-natural products.

Machine parts

The cleaning industry wants to advance to the next level – autonomous machines – and the demand for cleaning robot components has begun. Meanwhile, there has been a definite uptick in those manufacturing regular sweepers and scrubbers, as well as material handling equipment for warehouses, in India. “Some small players have also entered this market”, said Abhay Soni, Head, New Business Development, Amer NSM. “We may see a boom in 5-10 years.”

Make in India

Since the past three years, Schevaran-Cleanfix has been making in India; initially from another entity’s facility but since last year, from its own. While it still imports certain critical parts, “We want to be as integrated as possible and aim to make these parts ourselves within 6-8 months”, said CEO Alex Cherian.

He is confident of the immense potential of the market; the refrain of most exhibitors was that even smaller spaces are seeing more mechanised floor cleaning, which has become the baseline for any professional FM company.

Sakshi Gothwal, Proprietor, Vac-Clean showcased a newly launched three-disc machine for industrial use, with nylon, wire and heavy-duty wire brushes; if one phase doesn’t come on, the machine automatically stops to prevent damage. “From motors to pipes, we manufacture everything for other manufacturers. At the Show, we’ve met 3-4 companies interested in making domestic and industrial vacuum cleaners”.

The hygiene segment has also witnessed the growth of Indian players. Elegant Hygiene introduced hand towel roll dispensers, sought after by corporate offices, airports, railways and hospitals. Their ability to smoothly release sheets without tearing, even when pulled at by wet hands, reduces tissue wastage. Said Director Bharat Arora: “We are India’s first integrated production house, starting from drawing, designing, mould making and moulding of products. With increasing disposable incomes and a heightened focus on cleanliness, we anticipate a 30% Y-O-Y growth in the hygiene sector”.

Cleaning robots

After initially targeting pharma and automobile manufacturing, Peppermint Robotics has expanded to other sectors like aviation. Stating that robots are offered both on hire and as outright purchases (depending upon customer preferences and budgetary constraints), its CEO Runal Dahiwade said: “95-99% of the components are made in india. The robots you witness in action here are not just for the Indian market but also sought after internationally”. After the US and the Middle-East, it will soon venture into Europe.

FM players who operate in warehouses, hospitals and malls showed a lot of interest in robots at the Show.

Specialised solutions

Certain solutions for unique cleaning challenges were a match made in heaven. For example, accumulation of dirt on solar panels reduces power generation; SK Intech Metchem’s chemical is designed to work with machines and tools to clean them.

How can one clean the surfaces of industrial machine components? “Our ultrasonic cleaning baths reduce chemical usage, and are favoured by electronics, aviation, railway and consumer product segments”, said Director Shan D Nair. “We examine customer-specific challenges and develop specific solutions”.

Pigeons can gnaw through the fine nets that cover buildings, but are repelled by smell of the repellent gel supplied by Elevon Enterprise India. Non-toxic and biodegradable, it is effective for up to six months at a stretch, reducing the need for repeated cleaning of bird droppings. “Many cleaning agencies have approached us at the Show”, said Founder Sonal Sadarangani. “A cleaning robot company told us that they can apply our product even on the 70th floor of a building”.

Modes

One step ahead of concentrated chemicals are the surface cleaning tablets introduced by Chemicality India. They reduce logistics costs, carbon emissions and usage of single use plastic for packaging. This exhibitor was one of several in the b2c space who were interested in exploring the b2b space.

“The cost is 50-60% less for the consumers. We are getting a very good response here from the procurement supply chain, and are planning to do contract manufacturing for global brands”, said Director Rajeev Gupta.

S Vanchinathan, Head Sales – SAARC, Buzil Rossari showcased gel-based chemicals which offer efficient cleaning with less product usage. “They’re especially beneficial for substrates like carpets, providing thorough cleaning without the need for excessive water or rinsing”, he said.

Substitutes

Bio-Plastobag’s product line – made from corn starch-derived polylactic acid – can biodegrade within six months to a year. Demand has been fuelled by the ban on single use plastics, with purchases made by retail entities committed to sustainable packaging. “We want to target 40% of our production for exports to Europe and the Middle-East”, said Mudassar Ameen, Head, Business Development.

Private labelling

Most of Fresno and Bakersfield India’s business comes from manufacturing cleaning, laundry and dishwashing chemicals which are then private-labelled by hospitality, healthcare and large retail clients. Packaged in 50 litre and 100 litre containers, the product line is also baby-friendly – an added draw. “We’ve had quality visitors coming in”, said Creative Director Kinjal Trivedi. “Exporting to Dubai and North America constitutes a major part of our business”.

Revachemical is also into manufacturing chemical concentrates for private labelling by electronics, automobiles, pharma and an emerging sector – toy making. MD Jigar Shah said: “Our strength is R&D and manufacturing of chemicals, and we bank on it, leaving branding to others”.

Air quality

The pandemic-driven frenzy for air care has settled into a sustained emphasis on indoor air quality maintenance. Introducing his product to the Indian market at the Clean India Show was South Korea’s Charles Lee, CEO, Pillars of Creation. His combination of sensors measures carbon dioxide levels, dust, humidity and other parameters, alerting facility managers to make interventions when necessary. The company is looking to make-in-India.

Fragrancing

A host of scent diffusers and aroma oil dispensers made their appearance in this edition of the Show. While traditionally associated only with the hospitality sector, these products are now recognised for their role in enhancing mood and productivity, and influencing shopping habits in various sectors like corporates, airports and retail.

Think Hygiene launched a signature scent service, which creates exclusive fragrances for a brand, enhancing customer recall. While the hospitality sector remains a primary client, it also caters to the automobile showrooms.

Paper towels

Almost written off during the pandemic, these products are back with a bang. Saraya Mystair Hygiene introduced two-fold paper towels which are more affordable, easier to dispense and reduce consumption by 25-30% compared to three-fold towels. Also on offer was a centrifuge FRT toilet roll meant for heavy users like BPOs, which reduces wastage – an important selling point.

“Earlier, our major consumers were only large IT companies and airports. Now, we see demand coming from medium and smaller-sized companies as well”, said CEO Rajesh Gupta. “We were doing a lot of direct sales earlier; now, we are dealing with distributors who cater to smaller customers”.

Essity brought solutions for the industrial segment as well; paper dispensers which can be clipped onto trolleys to clean up grease, oil and other solvents on the go, reducing response time. A low-lint range for aviation, automobile and pharma industries was also of note.

Hand dryers

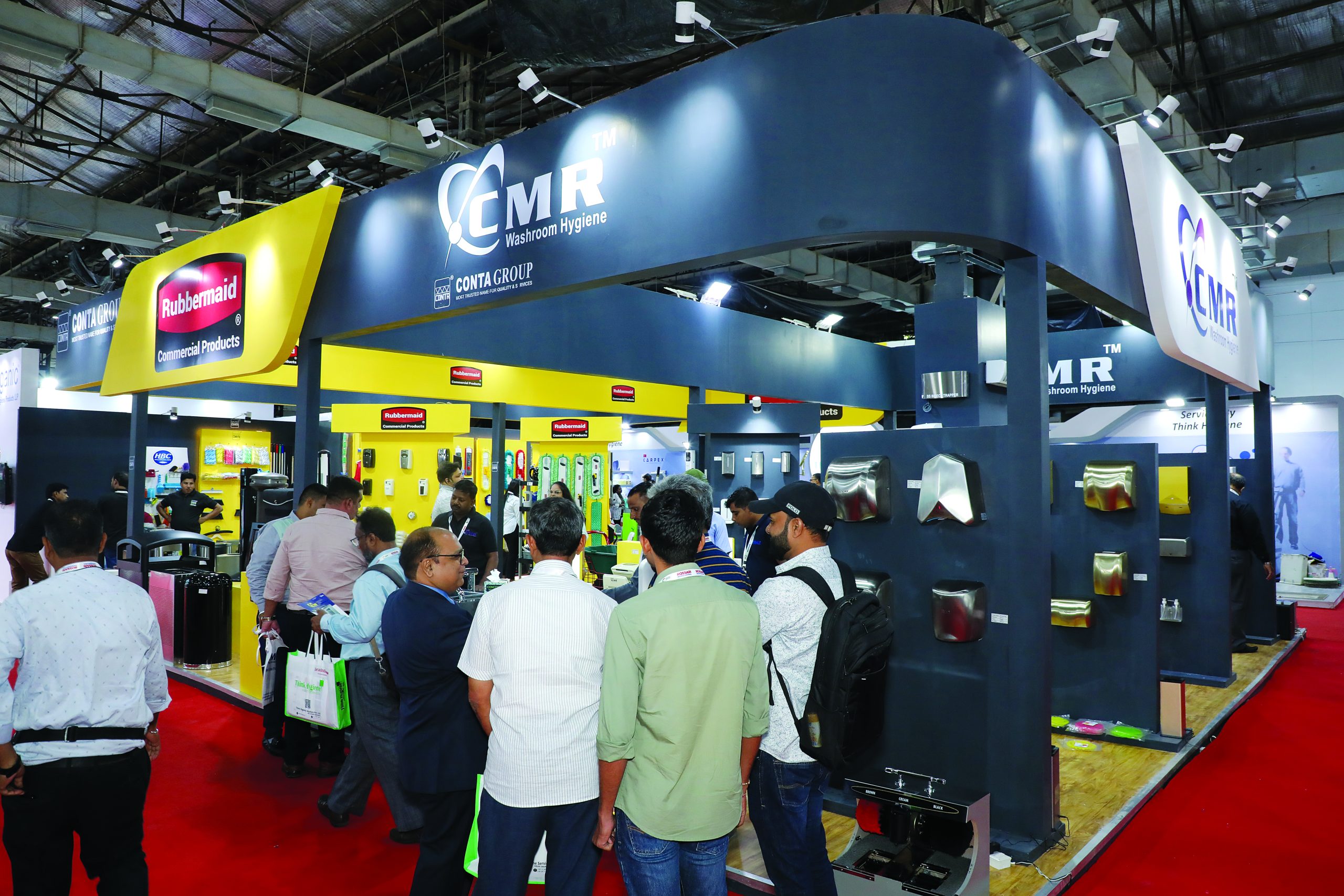

Hands-in models were sought after by high-traffic facilities like malls and airports; they do not allow water to drip onto the floor, eliminating the need for someone to constantly mop the washroom. Industries like automobile manufacturing – where staff must get back to work quickly – are also keen. Premium clients ask for models with in-built HEPA filters. “In general, organisations which want to reduce waste choose hand dryers over paper towels”, said Himanshu Gupta, Director, Marketing & Imports, Conta Group.

Digitisation

Essity’s solution measures the number of people using a washroom, as well as the consumption of resources. “This enables a shift from static to need-based cleaning and maintenance”, said Isha Sagar, Key Account Manager, India & Maldives, Essity.

Sustainability

Backpack machines which use Accelerated Cleaning Systems’s nanobubble ozone technology – which needs 80% less water – were sought after by FM heads of large campuses. Kolan India’s enzyme-based products remove stains and odour, last longer than conventional chemical cleaners and also maintain the quality of surfaces without causing any deterioration.

Pest management

This segment is exporting like no other. “We have been exporting insect killer machines to Sri Lanka, Kenya and Arabian countries since 2014, and will enter Europe this year”, said Anil Bawiskar, CEO, Electronic Equipments. Brandenburg, which makes in India for export, is now supplying to India too. The fluorescent tubes of its insect light traps are being replaced by LEDs, which reduce energy consumption, costs and carbon footprint. Rohan Chavan, Senior Sales Manager, India Region said: “Unlike fluorescent tubes, LEDS don’t require specialised disposal, and are not required to be shatter-proof – a must for the food and pharma industries”.

Navin Rohatgi, Partner, Shaullintiger Hygiene Solutions, manufacturer of insect traps, air-curtains and rat repellents, announced: “We are looking for dealers as we are increasing production capacity”.

The Indian cleaning industry is booming like never before. What’s next in store?

CIJConnect Bot-enabled WhatsApp

CIJConnect Bot-enabled WhatsApp