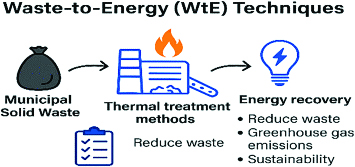

Municipal solid waste generation is rising worldwide, pushing governments and industries to explore technologies that can convert waste into usable energy while reducing landfill dependence. Waste-to-Energy (WtE) systems offer a dual advantage — effective waste treatment and renewable energy production — making them an important pathway in achieving sustainability goals and circular economy targets.

In an analysis by Soni, Sonu Kumar Gupta, Natarajan Rajamohan and Mohammad Yusuf published in Science Direct, highlights how WtE techniques can outperform conventional waste management practices and contribute meaningfully to climate and resource management strategies.

he huge generation of municipal solid waste along with the reliance on natural resources to meet the ever-increasing demand of energy has stimulated the world towards the exploration of novel methods for the recovery of energy and resources by using the generated waste.

Despite the numerous advantages of waste-to-energy (WtE) technologies, these techniques are not widely implemented. The researchers have summarized the various aspects of these techniques, including advantages and limitations, techno-economic analysis, challenges and prospects, framework and implementation.

The characteristics of municipal solid waste (MSW) vary with geographical conditions, living standards and socio-economic conditions. Therefore, no particular technique is equally feasible for the treatment of MSW. Strict environmental strategies, policies and guidelines can assist in selecting the best WtE practice.

The thermal treatment methods can effectively reduce the volume of generated waste by up to 90%. Techno-economic analysis has revealed that WtE techniques are economically feasible with suitable measures. Life-cycle assessments have found that these techniques can recover up to 27.40% of energy, depending on the process. Food and agricultural waste constitute 50-56% of the generated waste stream in developing countries, thereby highlighting the significance of anaerobic digestion.

The implementation of these techniques can considerably reduce the emission of greenhouse gases and is beneficial to environmental health. The potential for effective waste management and promotion of sustainability is underscored. WtE reduces landfill, pollution and CH₄ emissions while creating jobs. Biochemical methods suit food waste, gasification favours hydrogen production, and recycling is best for plastics. Policies and incentives can enhance adoption for a circular economy.

Thermal treatment, including pyrolysis, gasification, incineration and plasma gasification is the most commonly employed technique for the generation of energy in different forms and waste-to-wealth creation. In terms of energy and resource recovery capacity, pyrolysis is recognised as a more promising alternative when compared to incineration due to its ability to convert waste into higher-value fuels with reduced emissions.

Combined heat and power (CHP) are commonly employed as an alternative source of energy with a good energy conservation rate and is generally employed in incineration or anaerobic digestion plants. The feasibility of incineration and gasification for the conservation of energy through a stable source has recognised incineration as an effective approach to transforming urban waste into electrical energy by using a steam turbine. Consequently, the generation of solid waste and air pollution due to combustion are critical issues.

To reduce the emission of harmful gases from the incineration of waste, several post-treatment processes like carbon capture are employed with waste-to-energy facilities. The relatively high efficiency, ability of quick startup and shutdown, and the economy of combustion processes have made them a popular choice.

The operating condition, structural design and rate of fuel consumption are the factors that influence the generation of power. The gas turbine and micro gas turbine are employed for the generation of electricity from municipal solid waste.

The gas turbine utilizes combustion as a stable source to heat the compressed air, which improves the efficiency of energy production by the inlet gas. The micro gas turbine utilizes the syngas produced by the gasification of municipal solid waste with a high caloric value in the inlet gas. Biodiesel derived from different discarded oils can be a suitable alternative to petroleum-based diesel as a fuel for engines.

Besides combustion, fuel cells are a source of power generation from urban waste, but their sensitivity to impurities like chlorides, sulphides and particulates within syngas generated by municipal solid waste requires a purification system to maintain the service and life of the fuel cell. Due to their low sensitivity, matching operating conditions and favourable operating environments, solid oxide fuel cells (SOFCs) have drawn attention.

The microbial fuel cell relies on the anode of respiring bacteria allowing the production of electricity by using organic waste. Through their metabolic action, these bacteria release electrons from organic waste, and these electrons then flow through a circuit to the cathode and generate electricity, leaving behind water and CO₂ as the by-products. Although the technique is less polluting and reduces the issue of organic waste, it is still not commercialised. Moreover, the hybridisation of solar panels and wind turbines in a hybrid microgrid system can improve trustworthiness and efficacy by providing multiple energy sources.

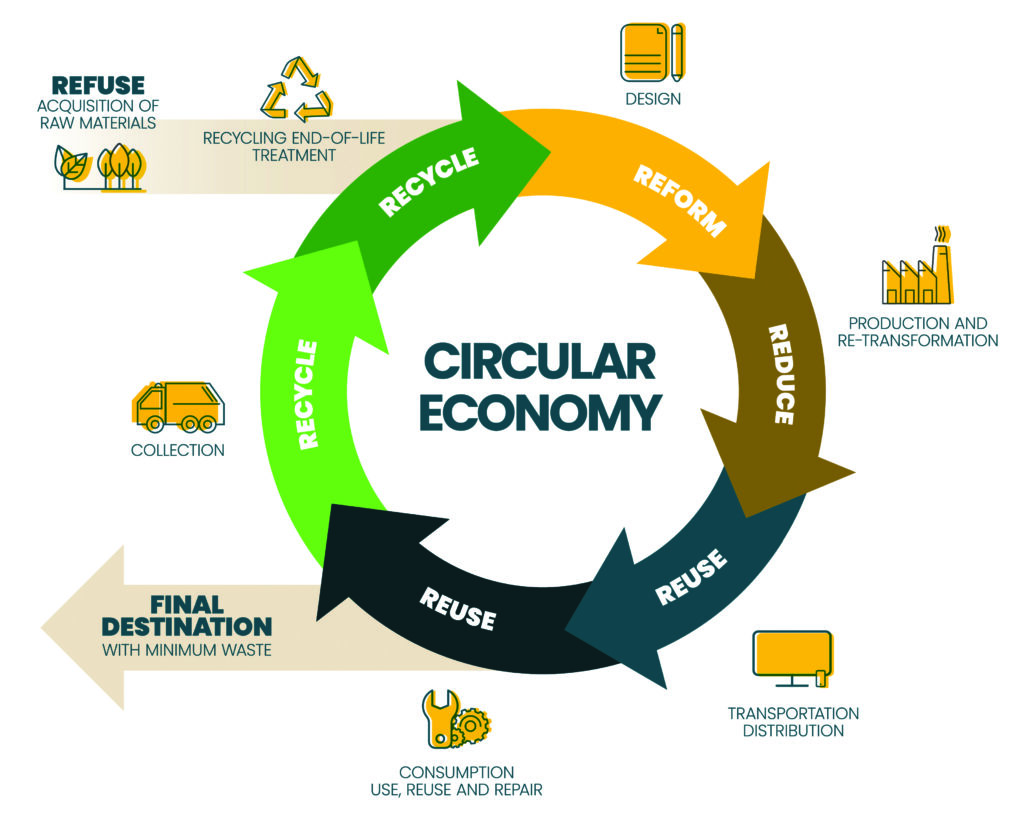

The recycling and reuse of feedstock and the elimination of waste in landfills are the prerequisites for an ideal circular economy. The waste-to-energy sector provides various business opportunities when strict pollution standards are being enforced by governments. Despite the low energy recovery efficiency of incineration, there are many feasible pathways for the recovery of energy through incineration.

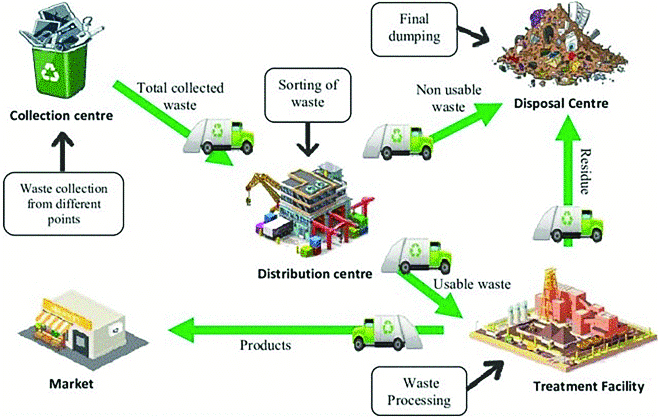

Although not every conversion technique is economically feasible, optimum pathways depend on the characteristics of the local supply connection. The wastes are collected, transported, sorted, preheated and finally transformed into a value-added product or energy, and the by-products are disseminated and eventually disposed of.

An optimised supply chain can reduce the impact on the environment and the cost incurred in the recovery of energy while increasing income from sales. A smooth flow of products, waste and by-products between supply points is of paramount importance.

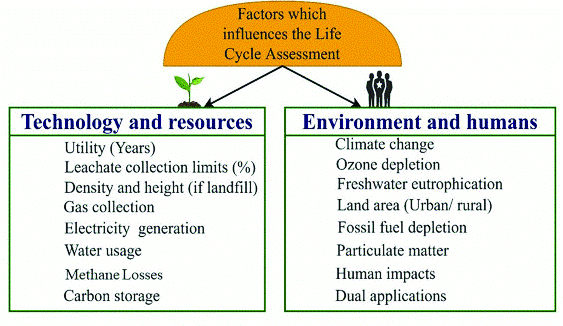

Techno-economic aspects considering technical viability and cost-effectiveness can be evaluated. An evaluation of the technical performances of different processes can assist in identifying a suitable technology for the attainment of higher return and efficiency. Therefore, the economic feasibility and technical performances are combined for a complete assessment of WtE techniques.

In general, the environmental considerations of the WtE process cannot be ignored, particularly with the growing focus on global carbon neutrality. Global warming is one of the primary indexes to qualify the influence of greenhouse gases against carbon dioxide. The waste-to-energy conversion of MSW is crucial for the attainment of net-zero pledges as it addresses the increasing rate of waste generation associated with economic growth.

There are different economically feasible approaches available for the recovery of energy having less environmental impact for each type of municipal waste. The WtE sector in India is still in its embryonic stage and is evolving over the years; the fraction of waste processed yearly in India is comparatively low in comparison with developed countries.

The problem due to the mismanagement of solid waste is becoming more critical due to the increased amount of waste resulting from the growing population. The management of municipal solid waste, including its assortment, transportation and storage, is deteriorating and requires immediate attention.

It is inferred that there are multiple factors responsible for the improper monitoring of solid waste in developing countries. Consequently, there is a pressing need to implement robust waste management techniques with minimal dumping.

Techno-economic analysis

The techno-economic investigation provides a comprehensive linkage between the economic and technical performance of waste conversion techniques.

Production, process efficiency and feedstock conversion are considered as the parameters for assessing technical performance, whereas the net profit value, return rate, payback period, cost of raw materials and selling price are considered as the economic factors.

Techno-economic analysis is a method for evaluating the economic and technical performance of a technology.

CIJConnect Bot-enabled WhatsApp

CIJConnect Bot-enabled WhatsApp